Major fields

Jewelry

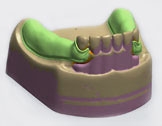

Dental

Toys and Miniatures

Automotive

Advanced Research and Education

Sporting Goods

Aerospace

Aerospace

Aerospace 3D Printing

Technology Takes a FlightMaking Flying a Better and Safer Experience

If you are underestimating the capabilities of 3D printing, there is only one thing you need to ponder about. 3D prototyping is widely embraced by the aerospace industry - a multimillion dollar industry where safety and quality are highest concerns. So, if that industry can trust 3D printing, all the skeptical arguments in your head are invalid. From rockets to commercial planes, and from helicopters to jets, digital printing is somehow involved in the designing and manufacturing process.

One of the biggest companies in the industry, Boeing, claimed to have made use of nearly 22000 3D printed parts in a year. Currently the 787 Dreamliner has nearly 30 3d printed parts in the actual craft. The company plans to use the technology to print wings and complex engine parts in the future. According to NASA officials, the use of 3D printed parts is quite prevalent in rockets and shuttle production as it makes it easier to capture the imagination of mission concepts.

The 3D Advantage

While it is established that the technology is quite commonly used in the industry, it is important to understand the benefits it brings to the table. There are more than many reasons that have compelled the giants to choose it as their preference.

- No Tool Technology- One of the major advantages of 3D printing for aerospace industry is the way it reduces the complexity of the process. All that is required to create a part of a prototype is the right material and the equipment that can work with that material. There is no requirement of any other tools and equipment.

- Durability - Accuracy, precision, and attention to details are three factors that play together to create a structure that is durable and stronger when compared to parts manufactured by other process. That is one of the main reasons the industry relies on this technology.

- Lighter-weight- Speaking of structure, 3D printing makes it possible to create structure that is lighter in weight. You can control everything ranging from texture to density resulting in a product that is as flexible yet durable as you want.

- Time Effective- 3Dprinting has the power to turn a matter of weeks into a matter of hours. Creating prototypes and functional parts is faster and a few digital tweaks allow you to create a newer and better product than the previous prototype.

- Cost Saving- There are a lot of factors that work together to make 3D printing a feasible and cost-effective option. There is lower wastage of material and the amount of resources and expertise required to get the job done is significantly low.

CAD PRINT WAX - On the Wings of Glory

While Aerospace industry is relying heavily on 3D printing, the quality they need is simply the best. That is exactly what we bring on board. We present an extensive choice of material to suit your needs and requirement the expertise we hold in this arena is unbeatable. We have worked with a multitude of clients, and we have proved ourselves every single time.

We focus on helping our clients achieve perfection through cost effective high quality 3D prints delivered in the least possible time. In order to discuss your needs with our experts, give us a call.